- Your cart is empty

- Continue Shopping

Aluminum Conductor Wire

Advantages

- High purity thick raw materials

99.99% Copper/99.6% Aluminum Safety, low resistance, stable voltage, more power saving. - Low eccentricity, uniform thickness

Prevent damage is guaranteed, effectively prevent the current breakdown, to ensure the safety of electricity. - Safer use, flame retardant and environment friendly

All new and high quality sheath, water-resistant and oil-resistant, soft and easy to install. - High cost-effectiveness

Environment friendly, safer use, better quality, low cost and sooner delivery.

Aluminum Conductor Wire

Aluminum Conductor Wire: A Comprehensive Guide

Aluminum conductor wire is a popular choice for electrical wiring due to its lightweight, cost-effectiveness, and excellent conductivity. It is widely used in residential, commercial, and industrial applications. Whether you’re wiring a building, setting up electrical grids, or working on high-voltage projects, aluminum conductor wire offers several advantages.

Benefits of Aluminum Conductor Wire

- Lightweight

One of the most significant advantages of aluminum wire is its weight. It is much lighter than copper wire, making it easier to handle, install, and transport. - Cost-Effective

Aluminum is more affordable than copper, which makes it a cost-effective solution for large-scale projects where long stretches of wire are required. - Good Conductivity

Though aluminum has slightly less conductivity than copper, it still provides excellent electrical performance, especially when used with the correct size wire for the current load. - Corrosion Resistance

Aluminum naturally forms a protective oxide layer, preventing corrosion and extending the wire’s lifespan in various environments.

Common Uses of Aluminum Conductor Wire

- Residential Wiring

Aluminum wire is often used in homes for branch circuits, particularly in older houses. Modern technology ensures it can be safely installed with proper connectors. - High Voltage Power Transmission

In power transmission lines, aluminum conductor wire is preferred due to its high strength-to-weight ratio, making it ideal for long-distance power transfer. - Overhead Power Lines

Its lightweight nature makes it a common choice for overhead electrical power lines, reducing the need for heavy-duty support structures.

Safety Considerations

While aluminum conductor wire is highly effective, it’s important to follow safety guidelines during installation. Always use connectors designed specifically for aluminum wire and ensure proper maintenance to prevent issues like overheating.

By choosing aluminum conductor wire, you’re opting for a cost-effective, reliable solution suitable for a wide range of electrical applications.

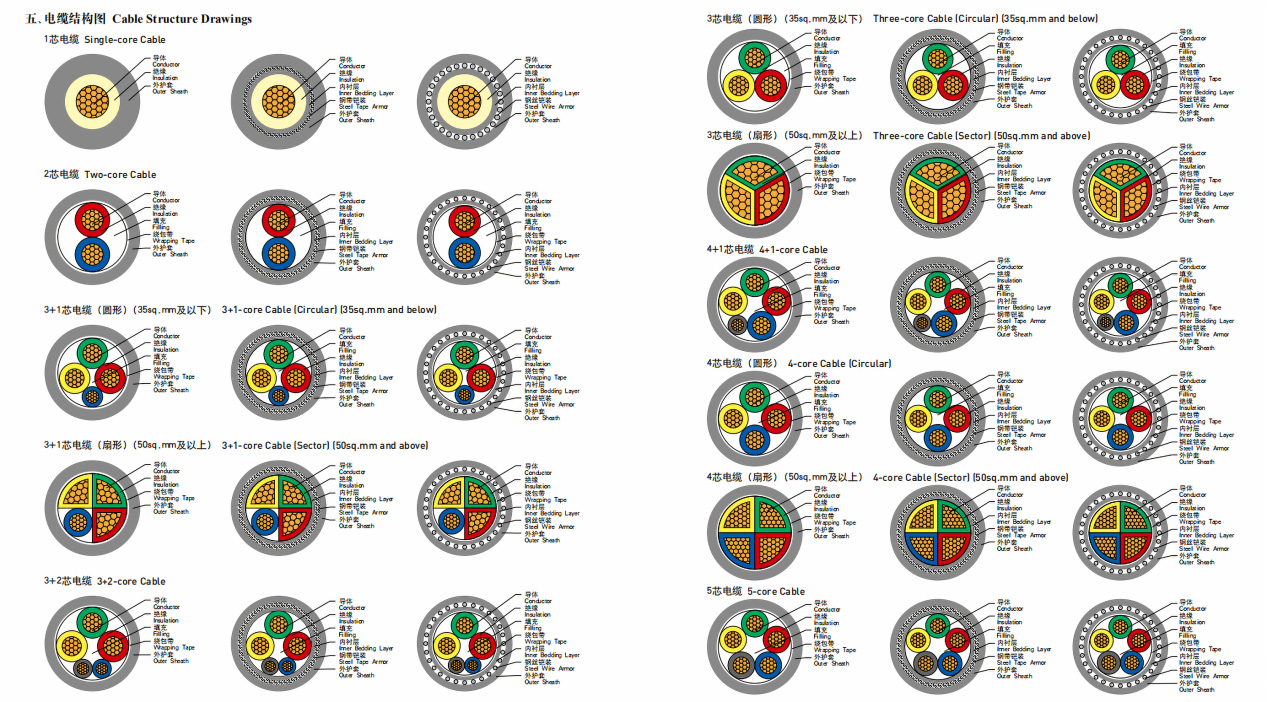

| O.6/1kV Aluminum Conductor XLPE Insulated Cable | |||

| Aluminum Cable Models | Description | Cores | Cross Section Area |

| Al/xlpe/pvc | aluminum core,

xlpe insulated, |

1 core 2 cores 3 cores 4 cores 5 cores 3+1 cores 3+2 cores 4+1 cores |

0.5~1000mm² |

| Al/xlpe/sta/pvc | aluminum core,

xlpe insulated, steel tape armoured, pvc sheathed cable |

4~1000mm² | |

| Al/xlpe/swa/pvc | aluminum core, xlpe insulated, steel wire armoured,

pvc sheathed cable |

||

| Note: Flame retardant cable and fire resistant cable are also available. | |||

| O.6/1kV Aluminum Conductor PVC Insulated Cable | |||

| Aluminum Cable Models | Description | Cores | Cross Section Area |

| Al/pvc/pvc | aluminum core,

pvc insulated, |

1 core 2 cores 3 cores 4 cores 5 cores 3+1 cores 3+2 cores 4+1 cores |

0.5~1000mm² |

| Al/pvc/sta/pvc | aluminum core,

pvc insulated, steel tape armoured, pvc sheathed cable |

4~1000mm² | |

| Al/pvc/swa/pvc | aluminum, pvc insulated, steel wire armoured,

pvc sheathed cable |

||

| Note: Flame retardant cable and fire resistant cable are also available. | |||

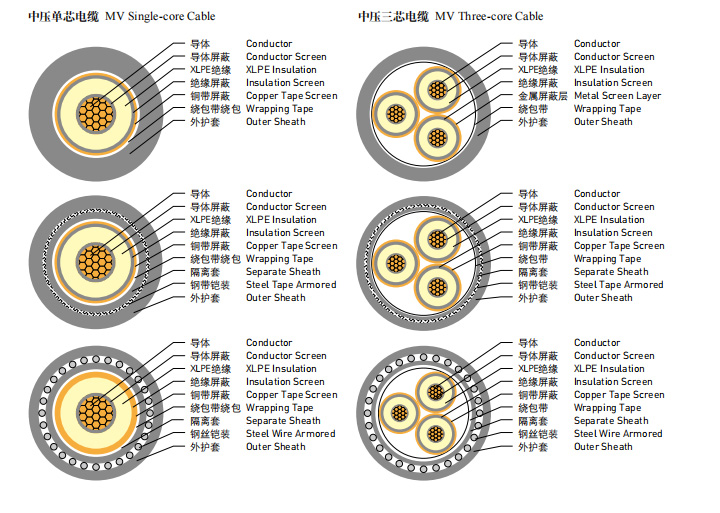

| Medium Voltage Aluminum Conductor XLPE Insulated Cable | |||

| Aluminum Cable Models | Description | Cores | Cross Section Area |

| Al/xlpe/pvc | aluminum core,

xlpe insulated, |

1 core

(sta, awa) 3 cores (sta, swa, awa) |

35~1000mm² |

| Al/xlpe/sta/pvc | aluminum core, xlpe insulated, steel tape armoured,

pvc sheathed cable |

||

| Al/xlpe/swa/pvc | aluminum core, xlpe insulated, steel wire armoured,

pvc sheathed cable |

||

| Al/xlpe/awa/pvc | aluminum core, xlpe insulated, aluminum wire armoured,

pvc sheathed cable |

||

| Note: Flame retardant cable and fire resistant cable are also available. | |||

Low Voltage Aluminum Cable Structure

| Voltage: | 1kV ~3kV |

| Conductor: | Aluminum Conductor (solid class1, stranded class2 ) |

| Insulation: | Crosslinked Polyethylene (XLPE) Polyvinyl Chloride (PVC) (optional) Polyethylene (PE) (optional) |

| Shield Layer (optional): | Copper tape(CTS) Copper Wire Braided (CWB) |

| Armour Type (optional): | steel tape armoured (sta) steel wire armoured (swa) aluminum wire armoured (awa) |

| Outer Sheath: | Polyvinyl Chloride (PVC) PE (Polyethylene) (optional) |

| Standards: | CCC/UL/CE/CNAS/IEC Certificate |

| Additional: | *FR, FRLS, LSZH, LSOH, LSHF, anti-termite cables are also available. *Customized products are supported. |

Medium Voltage Aluminum Cable Structure

| Voltage: | 3.6kV ~35kV |

| Conductor: | Aluminum Conductor |

| Insulation: | Crosslinked Polyethylene (XLPE) |

| Shield Layer: | Copper Tape Shield(CTS) Copper Wire + Copper Tape Helically Shield (optional) |

| Armour Type (optional): | steel tape armoured (sta) steel wire armoured (swa) Aluminum wire armoured (awa) |

| Outer Sheath: | Polyvinyl chloride (PVC) |

| Standards: | CCC/UL/CE/CNAS/IEC Certificate |

| Additional: | *FR, FRLS, LSZH, LSOH, LSHF, anti-termite cables are also available. *Customized products are supported. |

Characteristics

Temperature XLPE Material:

- Max. service temperature: 90 ℃

- Min. temperature when installation: 0℃

- Max. short-circuit temperature: 250℃ (max. 5s)

- Min. service temperature: -40℃ (fixed and protected installations)

PVC Material

- Max. service temperature: 70 ℃

- Min.temperature when installation: 0℃

- Max. short-circuit temperature: 160℃ (max. 5s)

- Min. service temperature: -40℃ (fixed and protected installations)

Min. Bending Radius

| Item | Single Core | Multi core | ||

| Unarmored | Armored | Unarmored | Armored | |

| Min. Bending Radius When installation | 20D | 15D | 15D | 12D |

| Minimum bending radius of the cable near the connection box and terminal (bending should be carefully controlled, such as with a formed guide) | 15D | 12D | 12D | 10D |

| * D means overall diameter of cables. | ||||

Advantages

- High purity thick raw materials

99.99% Copper/99.6% Aluminum Safety, low resistance, stable voltage, more power saving. - Low eccentricity, uniform thickness

Prevent damage is guaranteed, effectively prevent the current breakdown, to ensure the safety of electricity. - Safer use, flame retardant and environment friendly

All new and high quality sheath, water-resistant and oil-resistant, soft and easy to install. - High cost-effectiveness

Environment friendly, safer use, better quality, low cost and sooner delivery. - International standard meets different needs.

Our products are produced according to Chinese standards (GB/T, ISO9001) and international standards including IEC, BS, DIN, ICEA or according to customers’ requirements. It has also got CCC (China Compulsory Certification) and ISO certificates. Thus, the quality of each product could be guaranteed. - Quick response within 24hours.

Huanghe Cable Group supports you always. - Product warranty for one year if the product is correctly installed and used.

- Professional Team

Our engineer team support with professional suggestions and solutions. Customized products can be provided based on your specifications.